ALUMINIUM AND NON-FERROUS METALS

Endless Copper Tube

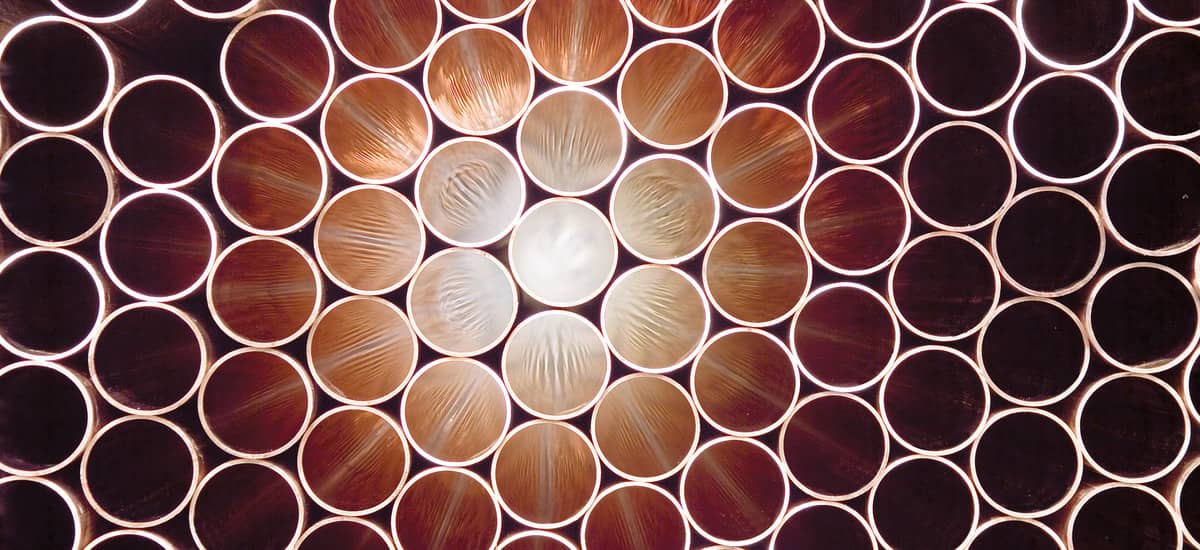

Danieli copper tube process has pure copper cathodes as the starting material, which are then melted and cast into thick wall tubes which are then cold rolled to reduce their diameter by the unique Danieli planetary rolling mill. High speed drawing in multiple stages then follow, with the final product being coils and/or straight lengths of high precision copper tubes with an exceptional eccentricity tolerance.

Endless Copper Tube

The continuous process from cathode to finished tube ensures minimum labor requirements while at the same time ensuring consistent high quality of the final product, as a very high productivity alternative process to the extrusion press route. Tube eccentricity is also excellent, thus yield loss is reduced to a minimum.

Numerous well established Danieli technologies, such as the ultra-high 400-m/min high speed chain-track drawing are incorporated into each ECT plant, ensuring the lowest cost per ton for such a process.

Direct contact

info.dcmk@danieli.com